Unmanned Weighbridge System: Revolutionising Logistics

In the ever-evolving landscape of logistics and transportation, efficiency is the name of the game. One groundbreaking innovation that is transforming the way we manage cargo and streamline operations is the Unmanned Weighbridge System. This blog will delve into the concept, benefits, and potential impact this cutting-edge technology can have on industries reliant on precise weight measurements.

- Understanding the Unmanned Weighbridge System: The traditional weighbridge process involves manual intervention, leading to potential errors, delays, and increased operational costs. The Unmanned Weighbridge System leverages automation and advanced technologies to eliminate these challenges. It allows for the unmanned weighing of vehicles, optimizing the weighing process and reducing human errors.

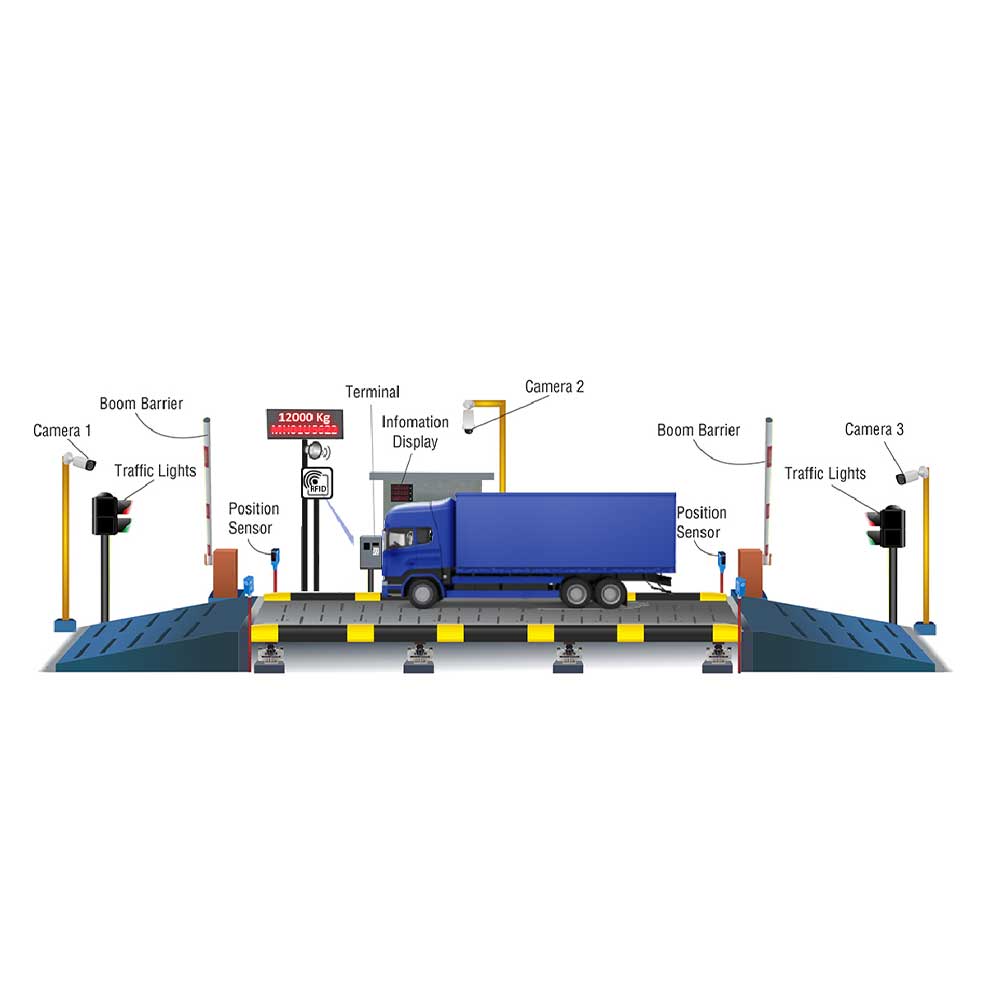

- How It Works: Unmanned Weighbridge Systems employ a combination of technologies such as sensors, cameras, and software to autonomously weigh vehicles. As a vehicle approaches the weighbridge, sensors detect its presence, triggering the system to capture images, record weight data, and transmit the information to a centralized database. This seamless process minimizes the need for human intervention and enhances accuracy.

- Benefits of Unmanned Weighbridge Systems:

- Increased Efficiency: Automation eliminates the need for manual data entry and reduces the time it takes to weigh vehicles, resulting in faster throughput.

- Enhanced Accuracy: Automated systems minimize the risk of human error in weight measurements, ensuring precise and reliable data.

- Improved Safety: With fewer personnel required on-site, the risk of accidents and injuries associated with manual weighing processes is significantly reduced.

- 24/7 Operations: Unmanned systems can operate round the clock, offering a more flexible and efficient solution for businesses with continuous logistical demands.

- Integration with Smart Technologies: Unmanned Weighbridge Systems can be seamlessly integrated with other smart technologies, such as RFID tags and GPS tracking. This integration allows for real-time monitoring of cargo, enhances security measures, and provides valuable data for inventory management and route optimization.

- Cost Savings and ROI: While the initial investment in implementing an Unmanned Weighbridge System may seem substantial, the long-term cost savings can outweigh these expenses. Increased efficiency, reduced labor costs, and minimized errors contribute to a favorable return on investment over time.

- Industry Applications: The Unmanned Weighbridge System has widespread applications across various industries, including logistics, mining, construction, and agriculture. Any sector that relies on accurate weight measurements can benefit from the efficiency and precision offered by this technology.

Conclusion: The Unmanned Weighbridge System represents a leap forward in logistics and operational efficiency. By harnessing the power of automation and integrating smart technologies, businesses can optimize their processes, reduce costs, and enhance overall productivity. As industries continue to evolve, embracing innovations like the Unmanned Weighbridge System is not just a choice; it’s a strategic move towards a more streamlined and technologically advanced future.

An important development in weighing technology, the Suraj Informatics Weighbridge Automation System provides numerous sectors with efficiency, accuracy, and security. It improves the functioning of conventional weighbridges and turns them into operator-free, completely secure systems with automation and cutting-edge add-ons. The Suraj Informatics Weighbridge Automation System is a shining illustration of how innovation is transforming weighing operations and boosting productivity and transparency as technology continues to advance.